Mi3 PROGRAM

Jump to navigation

Jump to search

MINOR ROBOTIC PRODUCTION & CIRCULAR MATERIALS @ ROBOTLAB

DIGITAL PRODUCTION WEEK 1 TO 4 MODULE 1

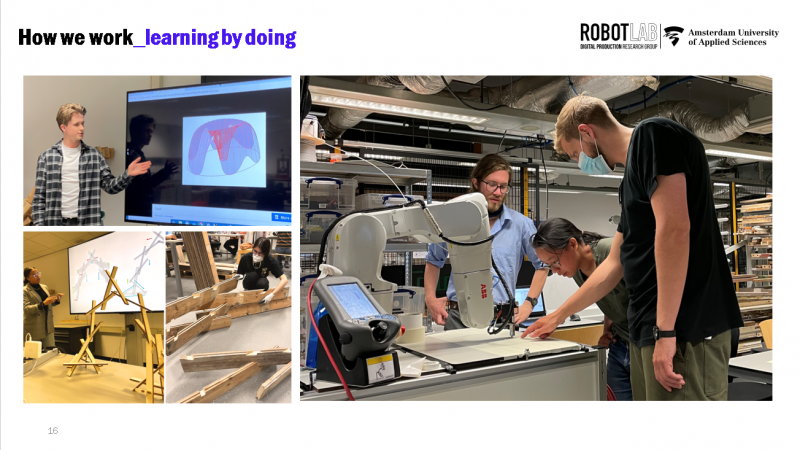

The first 4 weeks we will focus on the development of foundational knowledge on digital design and robotic production methodologies. We see digital production as a methodology for design towards production and not at the end of the process as the output of a pre-conceived design or representation. Shortly, production is but fully integrated in the iterative design process. With this approach we will test digital production methods to discover new forms and applications.

Throught a series of inspiring lectures, online learning courses and practical sessions with the Robots you will: * Understand the basics of computational design. * Explore an iterative digital design process. * Engage with computational design processes and use the digital production equipment present at school (Laser cutters, CNC Mills, 3D Printers and Industrial robotic arm with various end-effectors) you will learn how to alter the characteristics and performance of materials * Investigate advanced digital production methodologies to process the materials and explore complex production and/or assembly process, which characteristics can be controlled and customized with specific technology (i.e. custom end-effectors for the robot) and data.

MAKEATHON WEEK 5 AND 6 MODULE 2

Let's put our digital production skills in practice! The makeathon is a moment of application, and its a 2 week "marathon" where in groups you will "make" something. You will come together to create an object or piece of work that is environmentally friendly, unique, innovative and showcases the full potential of Digital Production. Therefore, the makeathon is used to meet, learn, have fun, and create together.

VISION ON CIRCULARITY WEEK 7 TO 9 MODULE 3

These 3 weeks are focused on learning and reflecting on the challenge of circularity. Through a series of inspiring lectures, online/live learning courses and practical coaching sessions we will dive into the topics of Material Research, Business Modelling and Impact Evaluation. Some of the objectives is to: * Understand the basics of material research, learn how to test, describe and determine the physical characteristics and properties of materials, with their weaknesses and strengths. * Connect with stakeholders that relate to these waste streams (who will you contact to get the material, understand what happens currently with the waste stream, the business model behind the stream, is this company interested in collaborating with you) * Explore the potential field(s) of application of circular materials and market. * Understand the basics of Business Modelling and formulate a new, innovative circular business model. * Explore impact evaluation methods such as KPI's or LTA's in order to critically evaluate a project.

CIRCULAR PRODUCTION APPLICATIONS WEEK 10 TO 17 MODULE 4

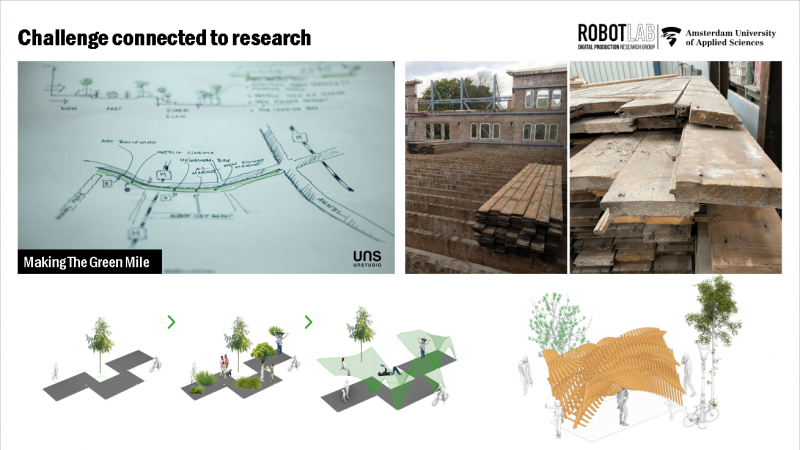

Within the context of the circular economy this minor is focused on the exploration of digital production methods and circular materials. So the main assignment is to create an innovative circular solution for a given circular or waste material, this challenge is connected to real cases from real companies.

You will explore the possibilities of rethinking and altering the characteristics and performance of this existing material and investigate innovative means of digital production to design and make entirely new circular applications. In this research, you will learn and explore how trough digital production methods we can process these “circular materials” to encourage more sustainable design and production solutions, leading to new business models for a circular economy, and/or other ways of addressing contemporary societal challenges.

In this module you will look at the given problem from different angles; based on the previous learnings. We think that by integrating these different aspects, it will be possible to come to innovative and viable new applications. These can range from a service, production process, new material to product, as long as it integrates the different aspects in a comprehensible way and solves the client’s problem. Our goal is to stimulate creativity, while aiming for innovation. The integration of disciplines is key to the main assignment.

The main objectives here are: * Connection with stakeholders that relate to the challenges (what happens currently with the material stream, the business model behind the stream, is this company interested in collaborating with you)

* Integrate the research outcomes of the different fields, through a creative iterative process, in order to create a realistic application. * Shows an iterative design to production process based on the need of the end-user and the application of the project * Formulate arguments and/or scenarios that express the added value of using Robotic Production and Circular Materials for audiences that may not be familiar with these topics. * Present and defend your integrated process and final product in a professional manner in a public setting.

EVALUATION & REPAIR WEEK 18 The time to reflect and improve / fix